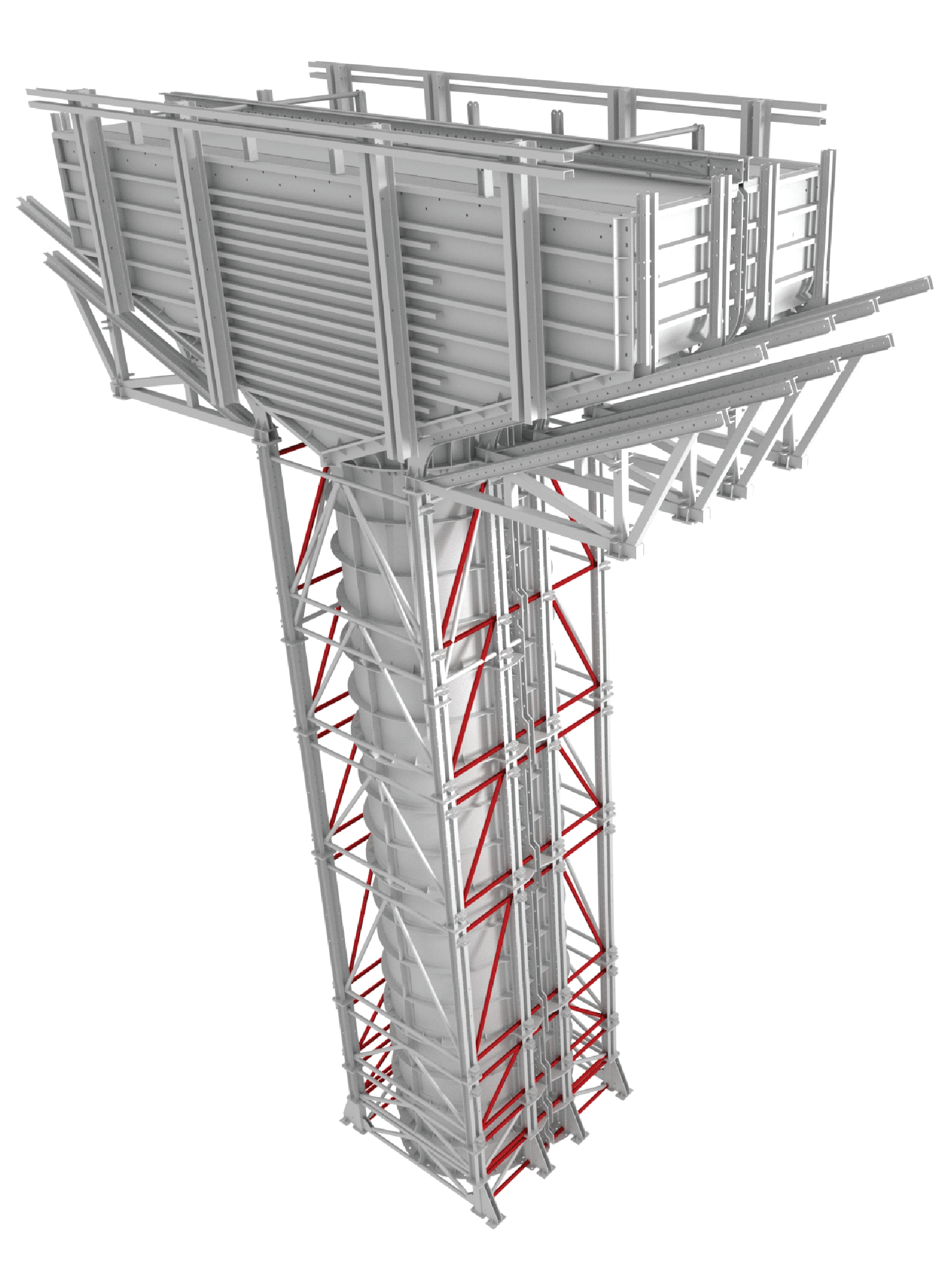

A versatile, customizable steel formwork solution engineered to accommodate diverse concrete shapes and dimensions. Renowned for its rapid and efficient on-site assembly with minimal labour demands, this system consistently delivers superior concrete surface finishes. Primarily employed in infrastructure projects such as bridge piers, flares, cross heads, cross beams, tunnels, culverts, and viaducts, its applications extend to specialized building structures and standard forms. Notably cost-effective for projects involving multiple repetitions of specific shapes, this system eliminates the need for supplementary fillings or boxouts. Its ease of erection, adjustment, and dismantling contributes to significant savings in labour and material costs. Manufactured using advanced techniques, the system consistently produces high-quality concrete surfaces, particularly in architectural finishes.

Supplied by WORCA

- Tailored Steel Panels

- Connecting parts

- Tilting items

- Access brackets (working & concreting platforms)

- Heavy duty brackets & Anchor

- Steel cones (in case of multiple vertical cast)

- Ladders & safety cages

- Tying items with ladders

- Bridges, piers, pier heads (flairs) & cross beams

- Tunnel form walls & slabs

- Special shapes columns & walls (architectural)

- Conical structures

- Pour rate: Up to 3m/hr

- 4mm steel sheet cladding (standard)

- Pouring height up to 12m

- Artilon patterns can be attached with steel panels in order to fulfill different architectural purposes

- Curved panels can be formed using high manufacturing techniques

- WORCA hi-skaf brackets can be also provided in case of multiple casts, in addition to WORCA special steel cage for pier head which facilitate and accelerate steel reinforcement work

- Tie-less solutions can be provided upon request.

- Top access platform (standard)

- Multi level access platform (upon request)

- Access platform with steel sheeting (upon request)

- Steel cage (upon request)

- Steel ladder

Supplied by Contractor