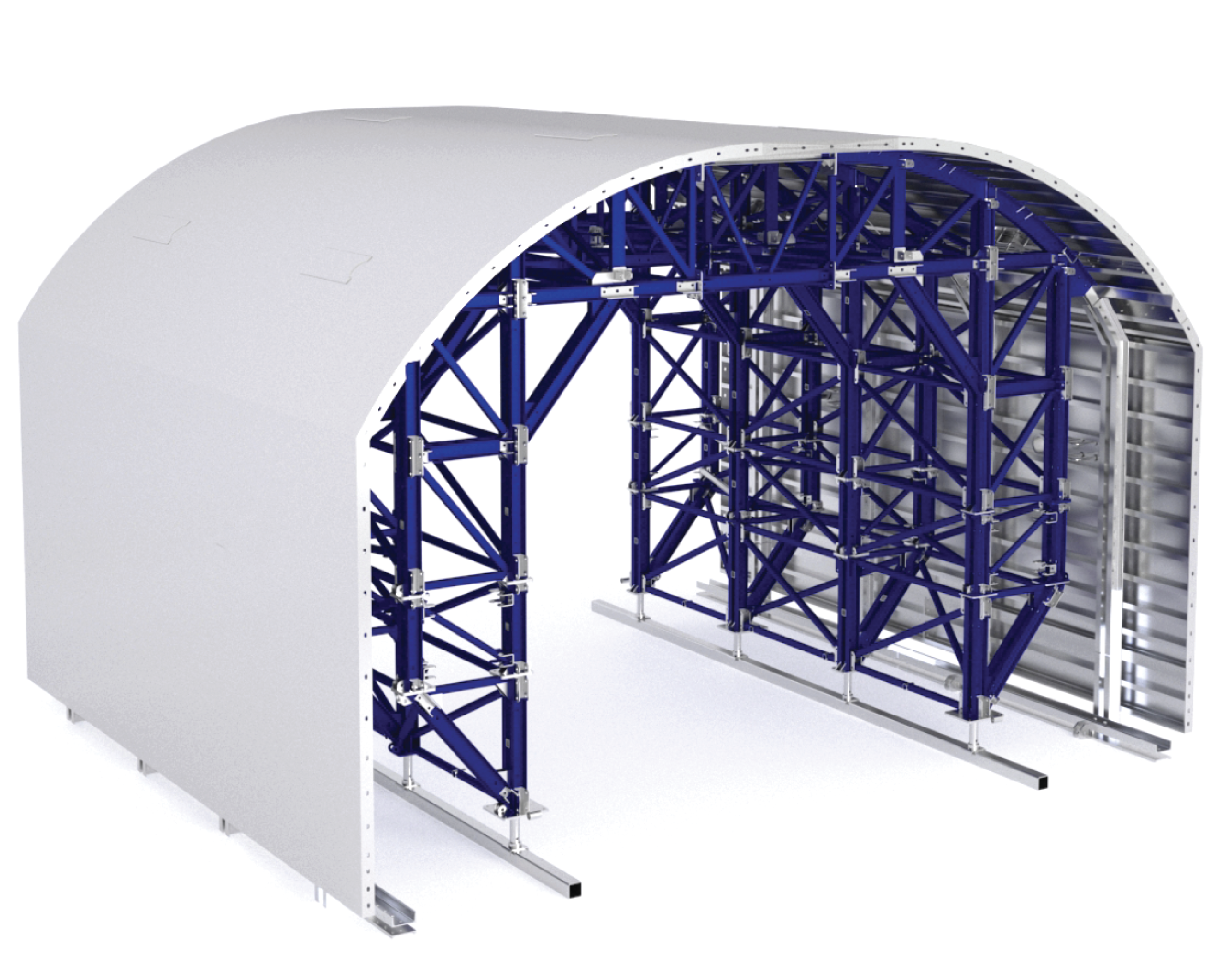

WORCA Tunnel Form System

A versatile system designed for the construction of cut and cover tunnels. It comprises shoring towers, soffit form, and inner and outer tunnel forms, which can be combined flexibly to accommodate diverse project requirements. This configuration enables rapid concrete pouring cycles while maintaining high load-bearing capacity, facilitating efficient and secure shuttering, striking, and movement operations throughout the construction process.

Main Components

Supplied by WORCA

- Decking panels for walls & slabs

- Shoring system

- Hanging, lowering & retracting system (manual or hydraulic)

- Moving / transportation accessories (manual or hydraulic)

Applications

- Cut & Cover Tunnels

- Underpasses

- Service Tunnels under various facilities

Features

- Walls & slabs are concreted in one cast

- Tunnel thickness up to 1.5m, and height up to 15m

- Full safety & full access (including platforms, ladders, handrails, etc.) is granted

- Adequate spaces for movement of trucks or other equipment inside the tunnel during work can be granted upon request

- Curves, inclinations and geometry variations can be solved by special designs

- Manual or hydraulic lowering & retracting mechanisms

- Manual or hydraulic transportation mechanism can be applied upon request

- Rails can be used to overcome rough grounds

- Steel reusable corners & fillers are used to avoid damaging the traditional timber corners & fillers at each stage during striking

Compatibility

- H20 / S12 WORCA Beam girders for decking, with straight or curved soldiers

- Tech-Form or Eco-Form panels can be used as well in certain cases

- Ringlock / Cuplock / Shorebrace Frames / Heavy Duty Shoring Towers can be used for shoring

- Special steel frames or HD Trusses can be used for special shapes as well

Site Requirements

Supplied by Contractor

Plastic Tubes

Timber Beams

Nails

Skilled Carpenter

Plywood