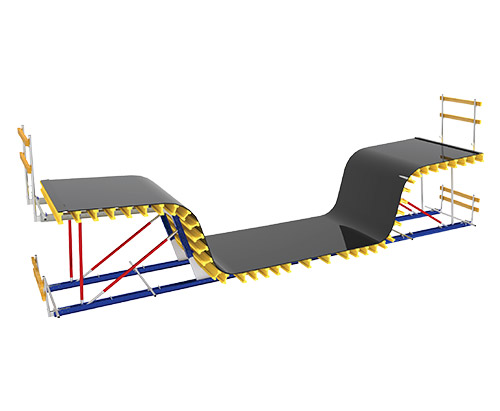

Stands as a preeminent solution for constructing a diverse array of bridge sections, each tailored to specific load parameters. A hallmark of efficiency, this system demands a singular assembly process at the project’s inception. Subsequent to this initial setup, the system’s components are readily transported between various construction sites with the aid of heavy machinery, including tower cranes, forklifts, or trucks. This unparalleled mobility significantly enhances operational flexibility and expedites the construction timeline.

Supplied by WORCA

- H20 timber beam / WORCA beam

- Main soldier

- Adjustable push-pull

- Safety handrail

- Upper curved splice

- Lower curved splice

- Bracing tubes

- WORCA board [upon request]

- Bridge decks of both uniform & variable sections [Depth and Width]

- Underpasses and flyovers

- Viaducts

- Table standard width: 2.5 & 3m [Can be tailored according to bridge design]

- Standard shoring: Shore-brace frames & WORCA Z-frames

- Alternative shoring types: Ringlock and soldier HD towers

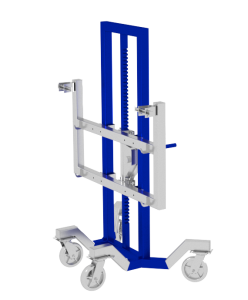

- Lowering device

For table lowering after concrete maturity

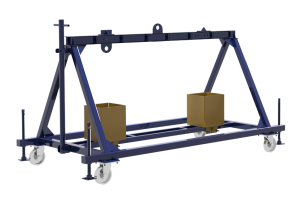

- Transportation wheel-jack unit

For shoring towers movement & reallocation

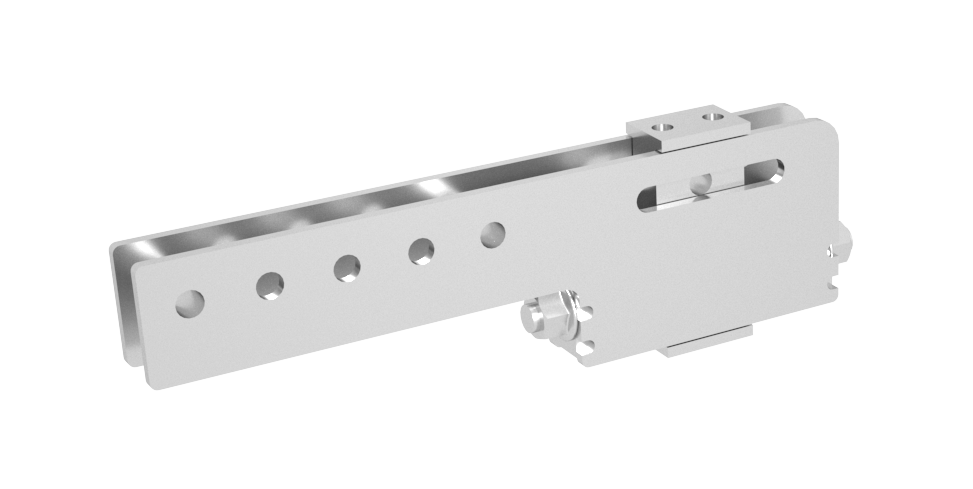

- Adjustable pivot splice

For side shutter adjustment [Retraction & Rotation] – in case of variable depth bridges

- Tailored curved splice

For curved soffit – web & top slab – web connections

Supplied by Contractor